Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

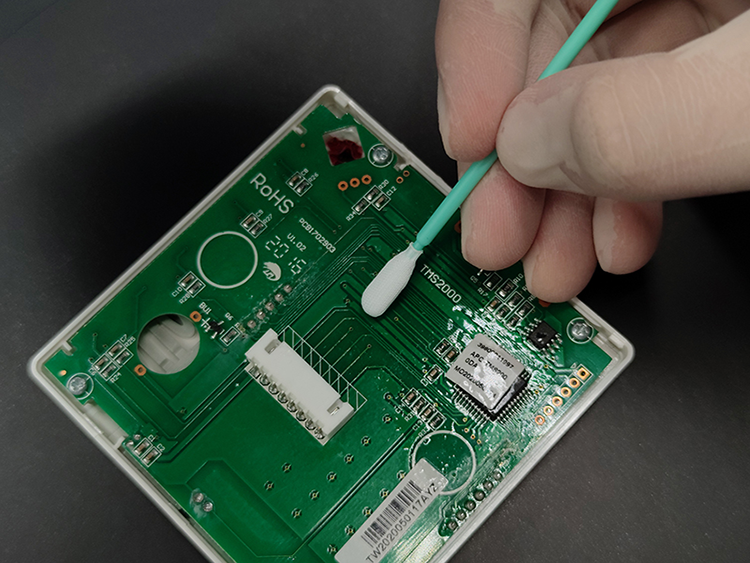

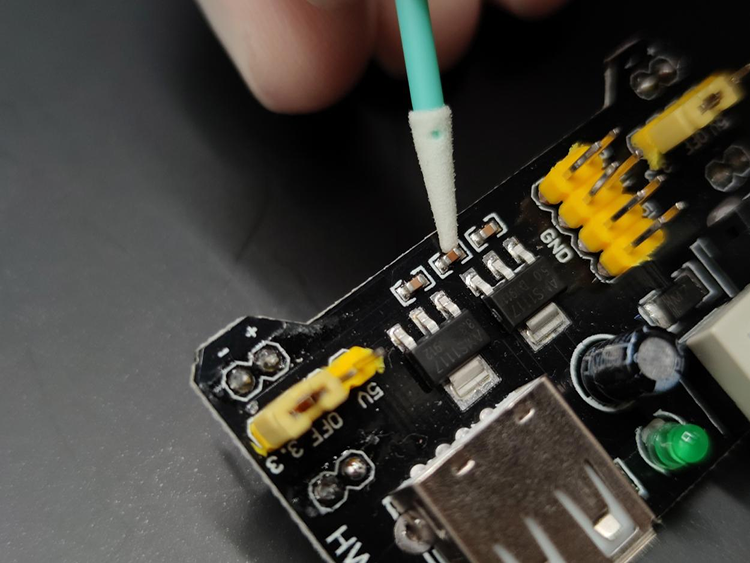

In precision cleaning applications, cleanroom swabs alone can be used to remove contaminants. However, it is more common to use a swab with a solvent to remove contamination. The success of your cleaning job depends in part on the compatibility between the swab and the cleaning solvent. A poorly chosen solvent can damage the swab tip material and cause more contamination, not less.

1.Swab Tip Material Compatibility

Solvent/swab compatibility is not an issue in most cases. The most common solvent for all types of cleaning is isopropyl alcohol (IPA), which is generally compatible with all types of swab materials. Sometimes stronger, less common, or even specialty solvents are required to remove stubborn contaminants such as excess adhesive, stains, coatings, bake-off flux, and some biological materials.

When the solvent starts to attach to the material at the tip of the swab (most commonly a foaming problem), the material will initially begin to swell. If the swab tip is simply heat fused to the handle, melting in one spot on the front and back, it will loosen very quickly. With prolonged exposure to harsh solvents, the foam begins to break down and break apart, creating a pile of particles.

2.Swab and solvent contact time

The contact time between the swab and the solvent is also a critical factor. Some cotton swabs are resistant to aggressive solvents for a short time, but break down over time. This is especially true when swabs are used to apply adhesives, bonding solvents, or lubricants. Technicians often use swabs for multiple applications, so the contact time is longer. The consequences are also more serious, potentially transferring contamination from the swab to the part, causing secondary contamination.

Concrete example:

- Aggressive solvents such as acetone can damage the polyurethane foam swab tip. Acetone penetrates, expands and softens the foam making it very susceptible to any abrasion, tearing, chipping and bulk particles and NVR (Non-Volatile Residue). Over time, the acetone will start to separate the individual polymer molecules, and the foam will even start to get tacky and leave a residue.

- However, acetone has little effect on most polyester swabs. Acetone is corrosive and has low surface tension, so it can penetrate between weakly bonded fibers. The seams on some of the finer cleanroom polyester swabs may be more easily weakened by acetone. The seams of the cotton swabs may crack over time.

Miraclean Cleanroom Swabs are stronger in material and construction and are designed to be unaffected by acetone.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.