Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

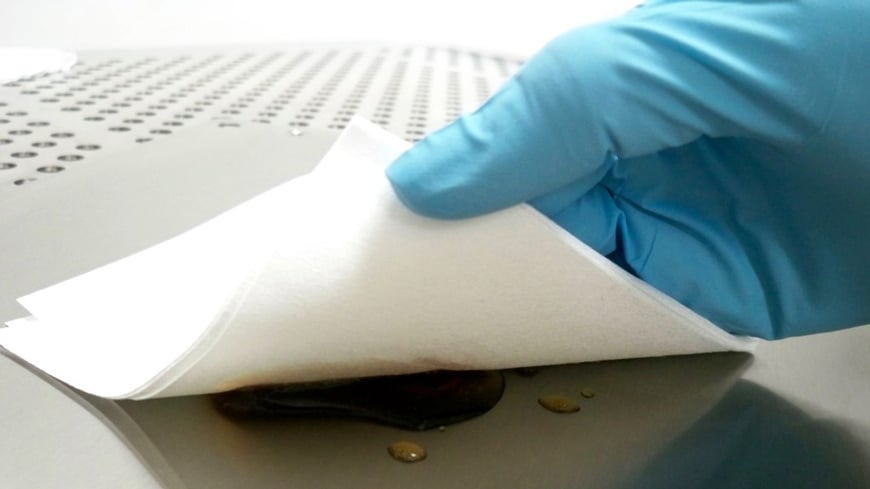

Water absorption: If the contaminant is solid powder, it is best to wet the Non-woven Wipes and wipe it to prevent the powder from scattering. This requires the dust-free cloth to have excellent water absorption, which can prevent dust from falling. If the contaminant is water or a mixture of solid and liquid, good water absorption and fast liquid absorption are all advantages. For daily use, I am quite satisfied that the water absorption performance of the clean cloth reaches 4 times the weight of the clean cloth. As mentioned above, super absorbency means making adjustments to the fiber configuration, which tends to reduce other indicators.

Dust generation: Dust generation and water absorption are two mutually exclusive indicators to a certain extent. Many clean cloths with good water absorption use lignin fibers (specific subdivisions can include wood pulp, viscose, Lyocell, etc.) These materials have good water absorption, but the difference in the amount of dust is relatively large, the difference between different fibers is large, and the difference between the same type of fiber but different origins is not small.The differences between different fibers are more pronounced in the presence of liquid, which relates to the concept of wet strength. Some fibers have poor strength in the wet state, and the fibers are easy to break or fall off from the dust-free cloth and become contaminants when wiping. In general, because of its abrasion resistance and strength, lignin fibers are difficult to reduce to very low dust emissions unless chemical additives are added, which brings other problems. In order to reduce the amount of dust generation, more wear-resistant high-strength fibers are mostly used. Polyester fibers on the market have become the unanimous choice of major manufacturers because of their high quality and low price. However, polyester fiber also has its weaknesses, water absorption is average (in the case of more liquid, the use of clean cloth or the number of Cleanroom Wipes must be increased, which means more dust generation), and it is easy to accumulate static electricity. Be cautious when doing so.

4)

Precipitation of ions and extractables: For some applications, in addition to the requirements for the amount of dust, the cleanliness of the product also requires that there be no precipitation and even the amount of certain metal ions must be strictly controlled. This type of application, such as lithium batteries, semiconductors and other products should minimize the presence of external ions. In order to achieve ultra-low ion precipitation and dust generation, it is often necessary to strictly control the process from the initial raw material (fiber) of the clean cloth to the production process of the original cloth, and then to the slitting and packaging.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.