Transportation:Ocean,Land,Air,Express,Others

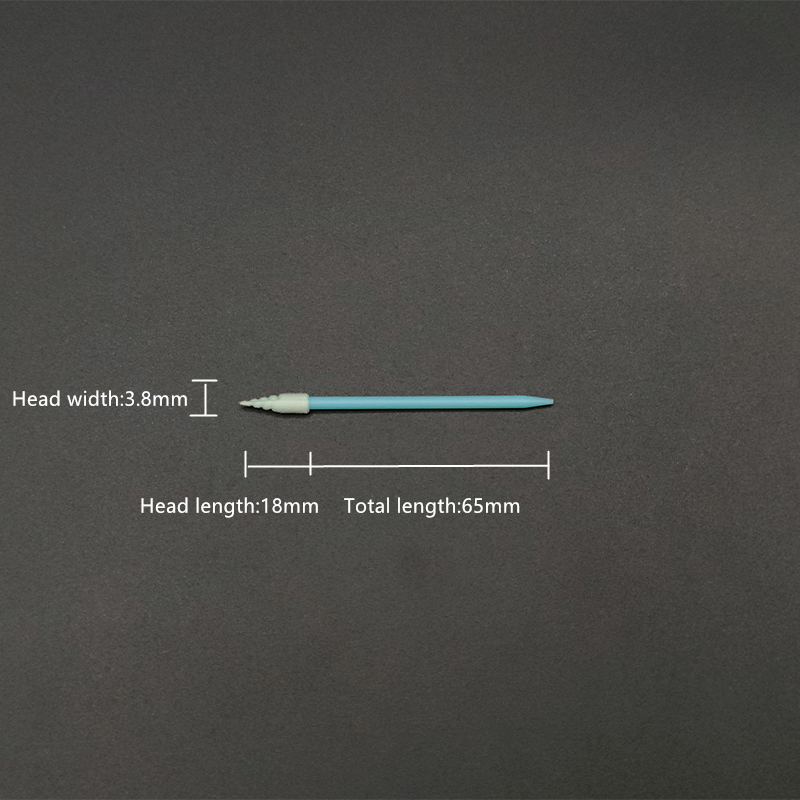

Model No.: MFS-751

Place Of Origin: China

Total Length: 65mm

Tip Width: 3.8mm

Tip Thickness: 3.8mm

Tip Length: 18mm

Handle Width: 2.5mm

Handle Thickness: 2.5mm

Handle Length: 47mm

Packaging: Packing Details: 100pcs/bag

Transportation: Ocean,Land,Air,Express,Others

How are dust-free Cleanroom Swabs produced?

The cleaning cleanroom swab is designed for cleaning tiny parts under strict dust-free purification environment. So the question is, how are the Disposable Cleanroom Swab, Lint Free Cleanroom Swab, Cleanroom Polyester Head Swab, Polyester Tip Cleanroom Swabs produced?

Since the cleaning Cleanroom Swab requires a very strict purification environment, we generally use the lamination process in the 1000-level clean room, and then transport it to the 10-level washing and drying center for cleaning and drying, and finally enter the 10-level Dust-free swab workshop for final cutting, collection and packaging.

In order to let everyone know more about the production standards of dust-free cleanroom swabs, the editor has summarized the following points to clear up your doubts:

1. Personnel entering and leaving process: Wear hair protective gear, gloves, masks, cleaninges and clean shoes, and must enter the clean room through the air shower according to regulations, and the cleanliness of the environment must be maintained in the clean room;

2. Material in and out process: When the material enters the clean area from the production area, the outer packaging must be removed in the buffer room through the material purification system (including the buffer room and the transfer window). If the outer packaging cannot be removed, the outer packaging should be vacuumed. After cleaning, enter the clean area through the air lock room or transfer window (cabinet) with door interlock;

3. Maintenance of production equipment: The air-conditioning system device is the main equipment to ensure the cleanliness level of indoor air, including various filters, clean workbenches, laminar flow hoods, air showers, transfer windows, air-conditioning devices, etc. Regular inspection is an important condition to ensure the cleanliness of the clean room;

4. Environmental management and control factors in the dust-free cleanroom swab workshop: It is necessary to conduct a full range of regular monitoring and testing of factors such as air pressure, wind speed, dust particles, illumination, and noise in the dust-free workshop to ensure that the dust-free room is always in normal operation.

Pointed Sterile Foam Tip Cleaning Lint Free Swabs

MFS-751 is thermally bonded by 100PPI open-cell polyurethane foam & light green PP handle, its cleanroom laundered foam head possesses high solvent capacity and good cushioning. It is free from organic contaminants such as silicone, amide and phthalate esters, and it features very low non-volatile residue (NVR), ion content and particle generation. MFS-758 is designed with a small compact round handle and a thin flexible paddle head, and it’s the ideal swab for cleaning components in confined thin groove space where thickness height is the major concern.

Product Features

① Free from silicone, amide and phthalate esters

② Low in particles, ion content and non-volatile residue

③ High solvent capacity, soft and non-abrasive

④ Compatible with most common solvents such as IPA

⑤ Designed with flexible head paddle & long compact handle

Product Applications

① Cleaning with solvents such as IPA

② Cleaning surfaces and hard-to-reach areas

③ Remove flux residues and excess materials

Specification of Other Hot Selling Cleanroom Swab

| Model No. | Total Length | Tip Width | Tip Thickness | Tip Length | Handle Width | Handle Thickness | Handle Length |

| MFS-707 | 129mm | 17mm | 9.5mm | 26mm | 6.5mm | 2.7mm | 103mm |

| MFS-708 | 125mm | 19.5mm | 10mm | 27mm | 6.5mm | 2.7mm | 98mm |

| MFS-712 | 124mm | 13mm | 7.5mm | 25mm | 5.7mm | 2.5mm | 99mm |

| MFS-740 | 163mm | 6mm | 5.5mm | 17mm | 3mm | 3mm | 146mm |

| MFS-742 | 68.5mm | 3.6mm | 3.5mm | 11.5mm | 2.8mm | 2.8mm | 57mm |

| MFS-750 | 77mm | 3.2mm | 3.2mm | 11mm | 2.4mm | 2.4mm | 66mm |

| MFS-751 | 65mm | 3.8mm | 3.8mm | 18mm | 2.5mm | 2.5mm | 47mm |

| MFS-758 | 70mm | 3.2mm | 2.5mm | 10.5mm | 2.3mm | 2.3mm | 59.5mm |

Miraclean Technology Co, Ltd.

Established in 2003, Miraclean Technology is a manufacturer specializing in producing Cleanroom Products & Printers Cleaning Products. In order to meet or even exceed the industry standard, the plant is completely equipped with DI water system, sterilization equipment and purification workshops. Miraclean is committed to providing More Reliable Cleaning products for the contamination control industry. We are continuously striving for advancement to meet the demands of the growing market.

Packing and Shipping

Certificate

Exhibition